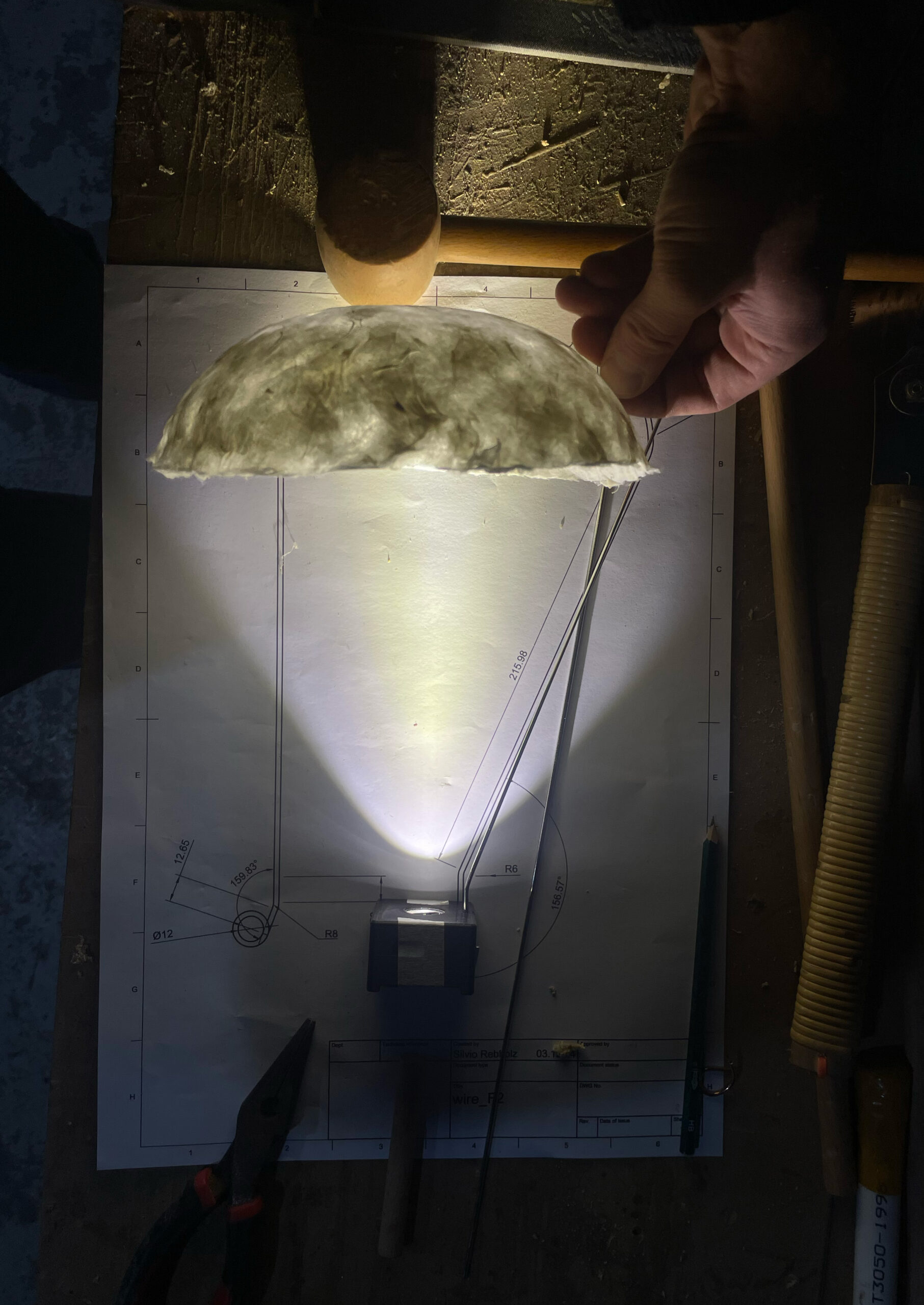

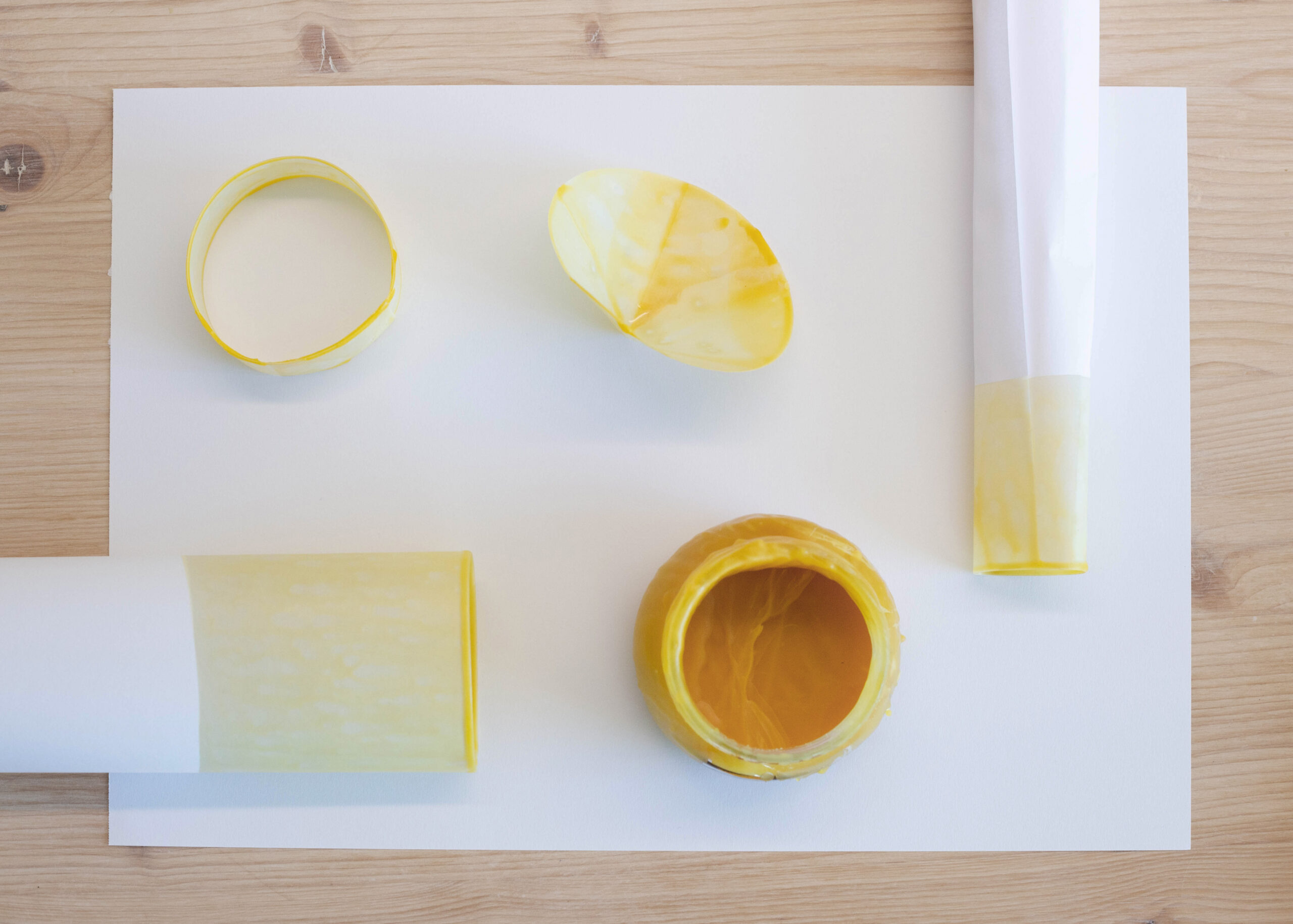

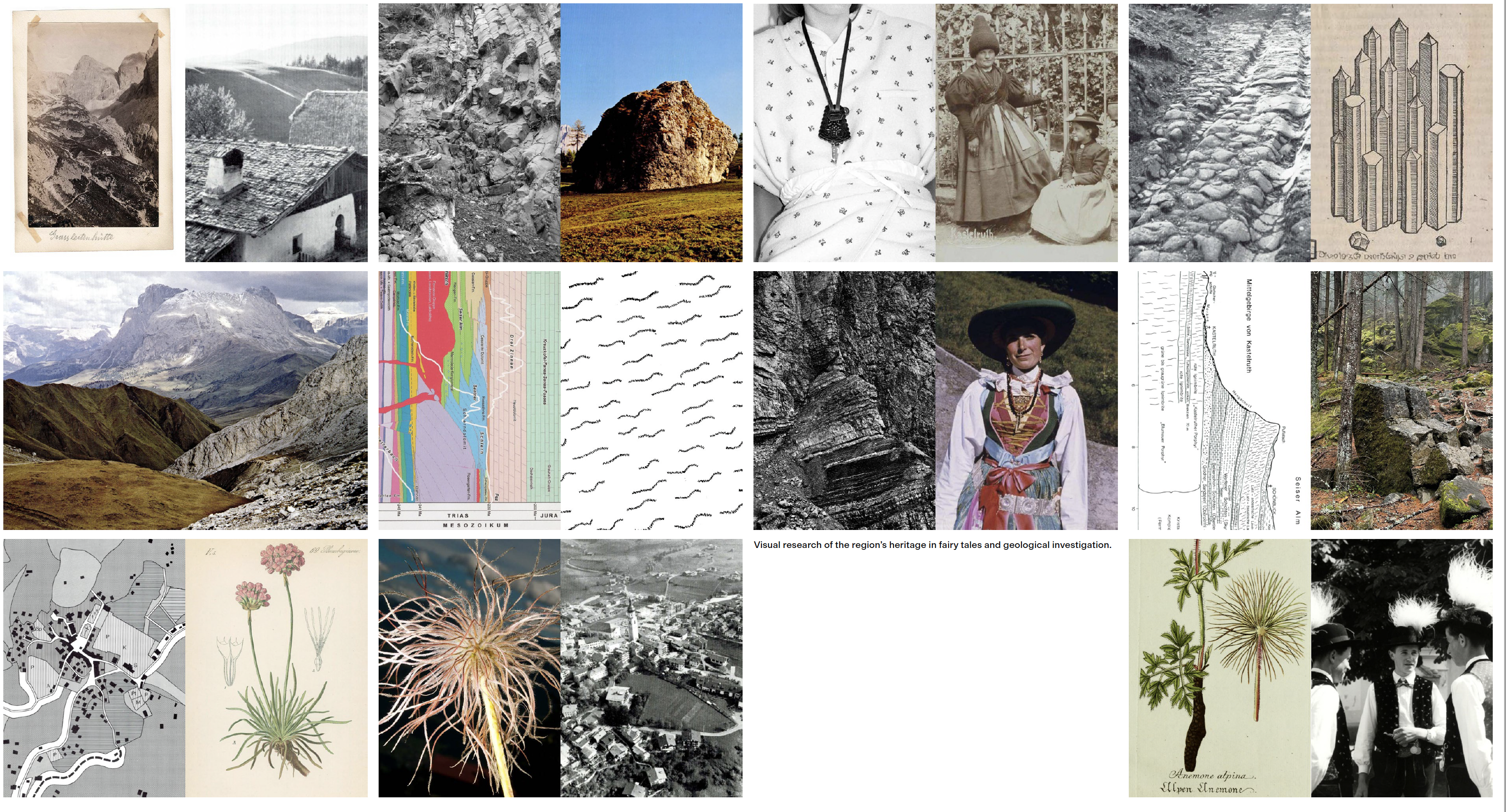

Visual research of the region’s heritage in fairy tales and geological investigation

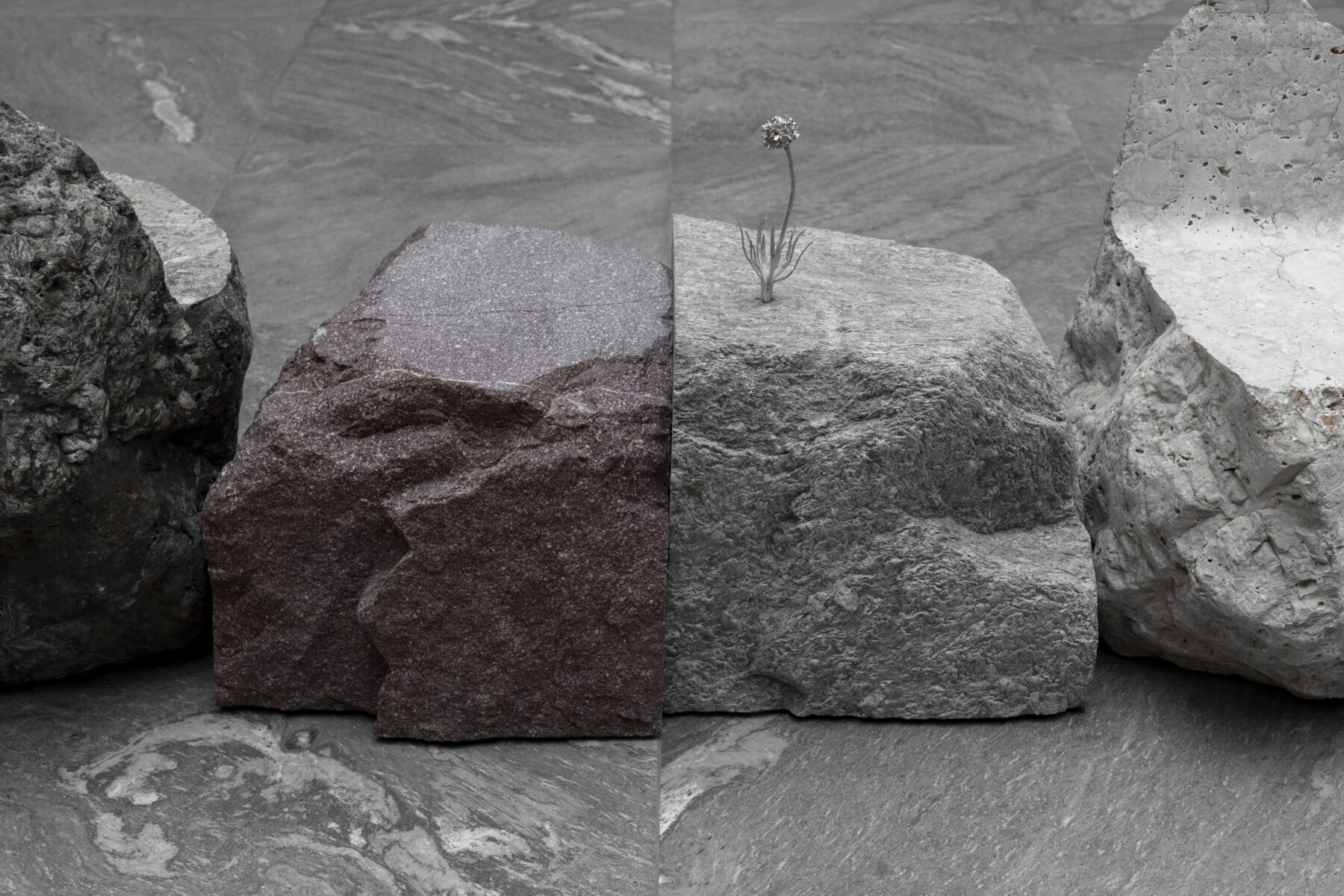

Konglomerat is a permanent installation in the center of the Dolomitian village Kastelruth, located in the entry hall of the local Raiffeisen bank. Surrounded by the striking Dolomites, Kastelruth is home to a rich tradition of myths and fairy tales—stories that once offered explanations for local geological phenomena in times when science could not. This tension between folklore and scientific knowledge became the central theme of this work.

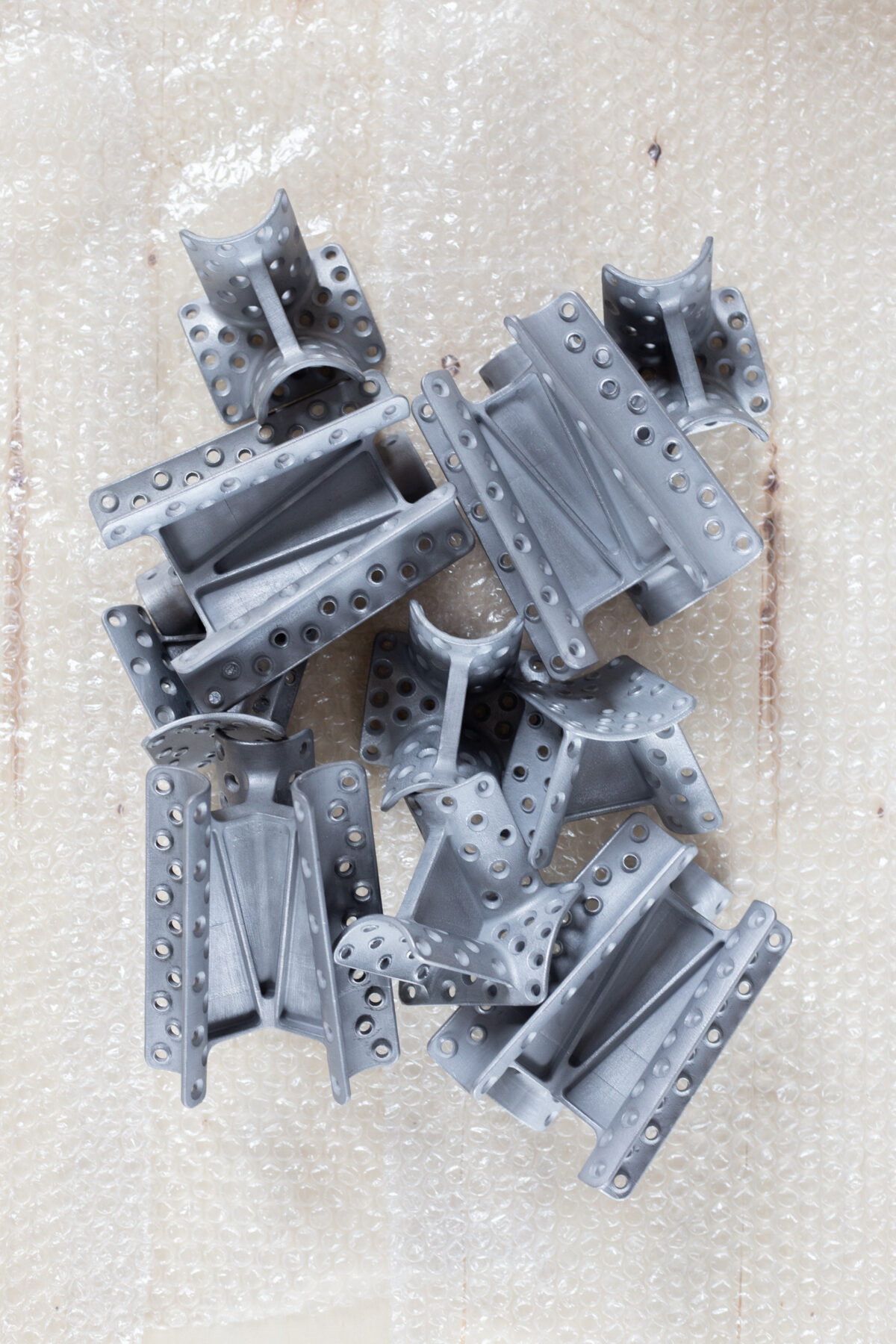

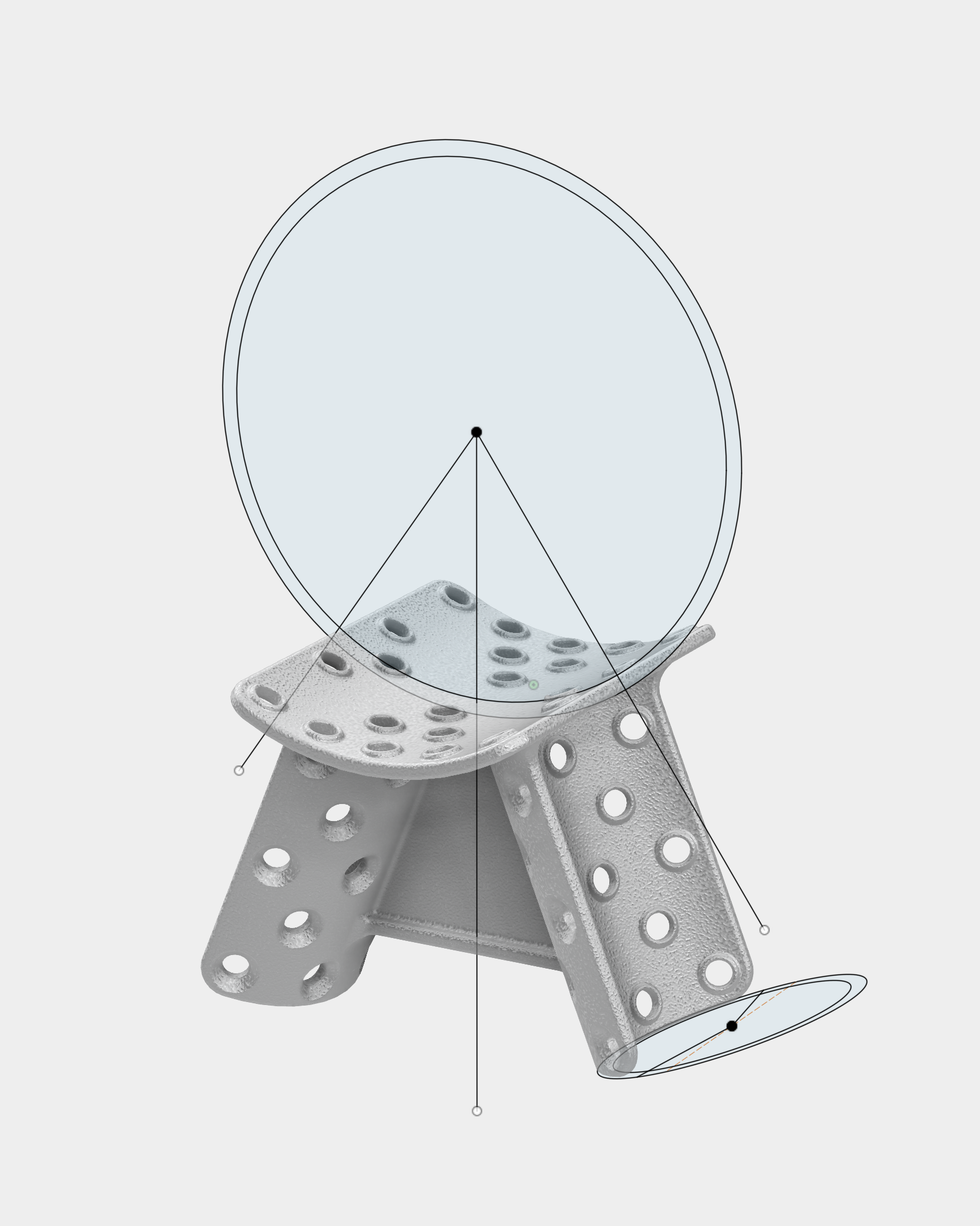

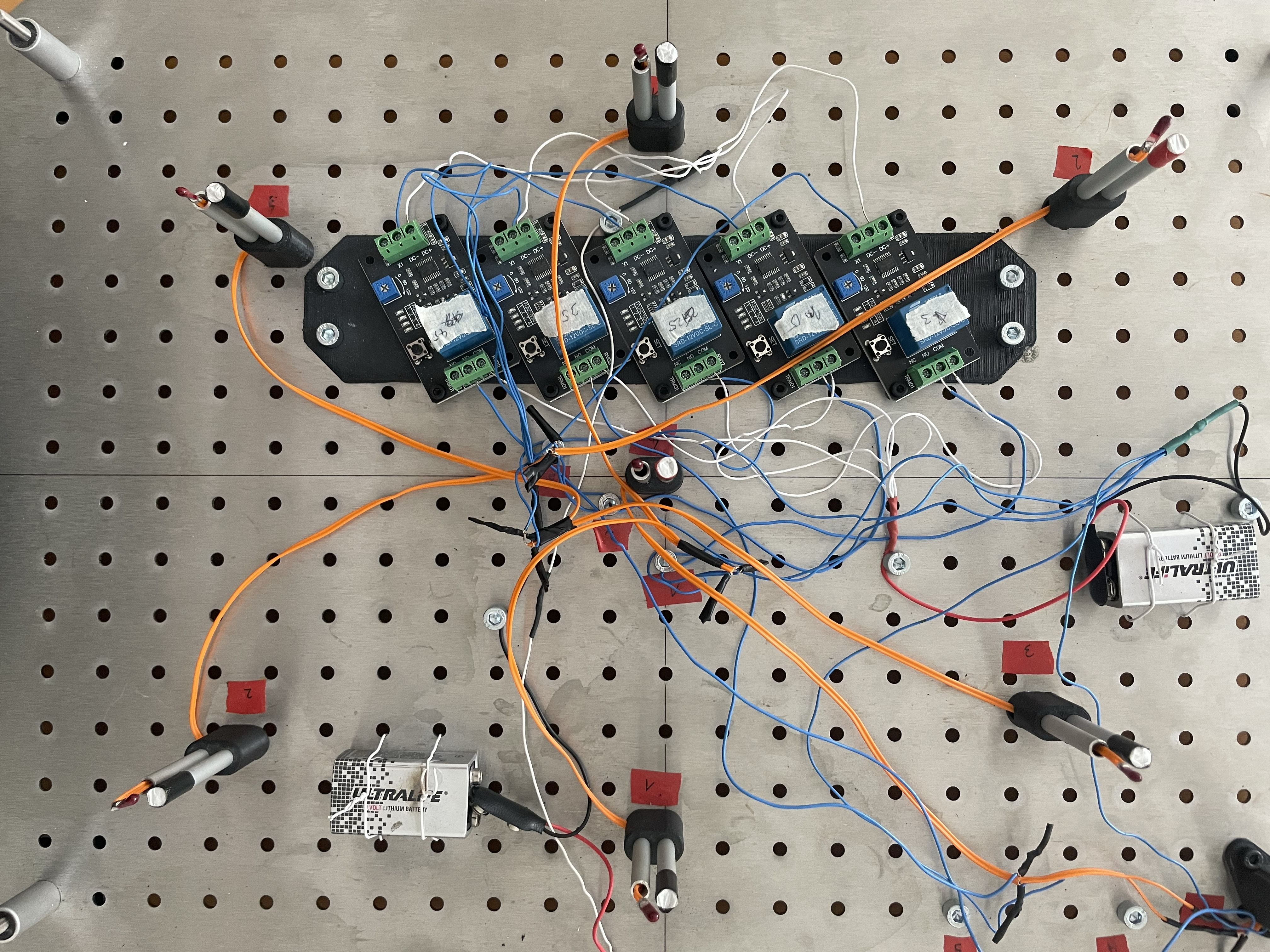

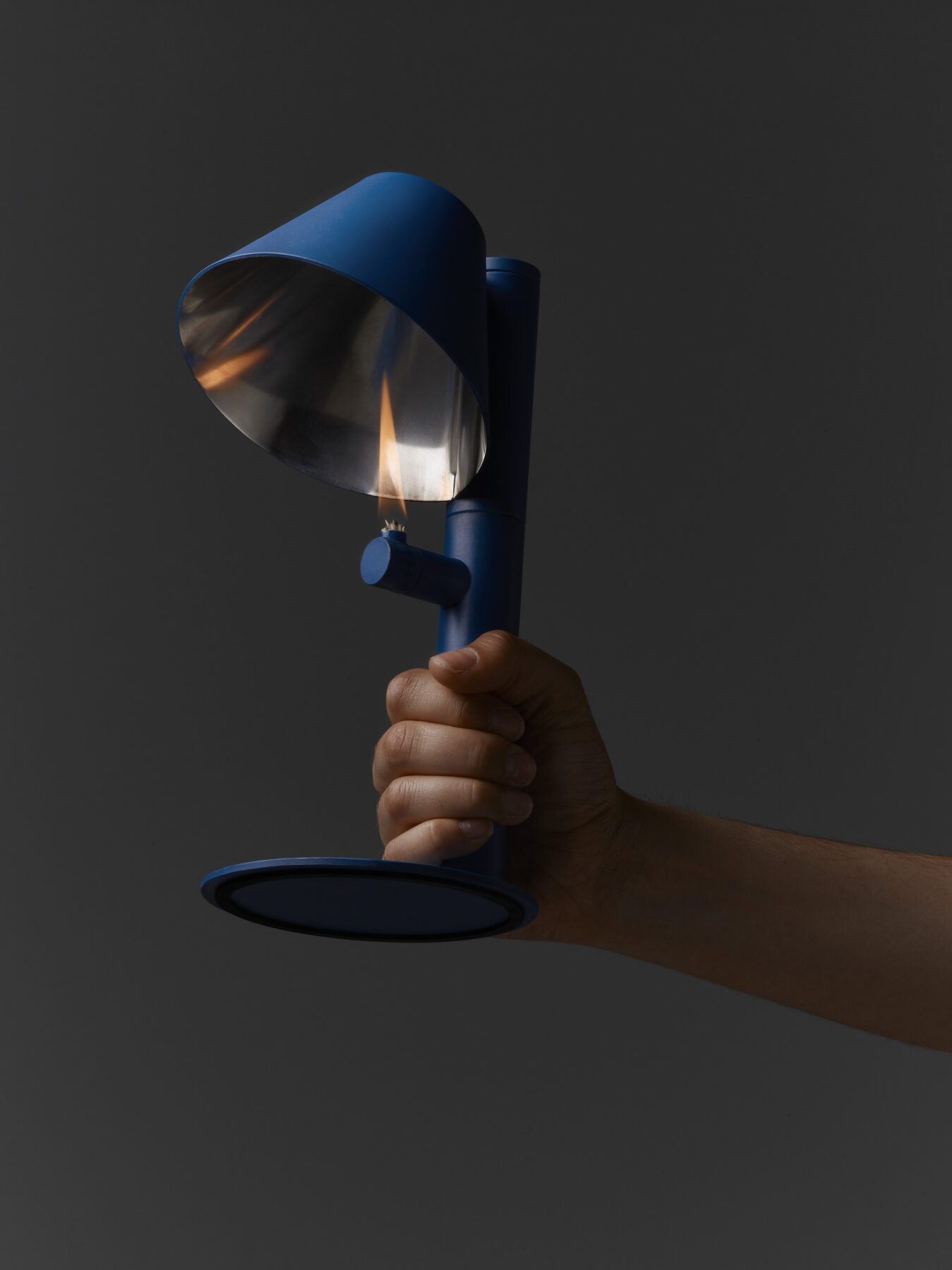

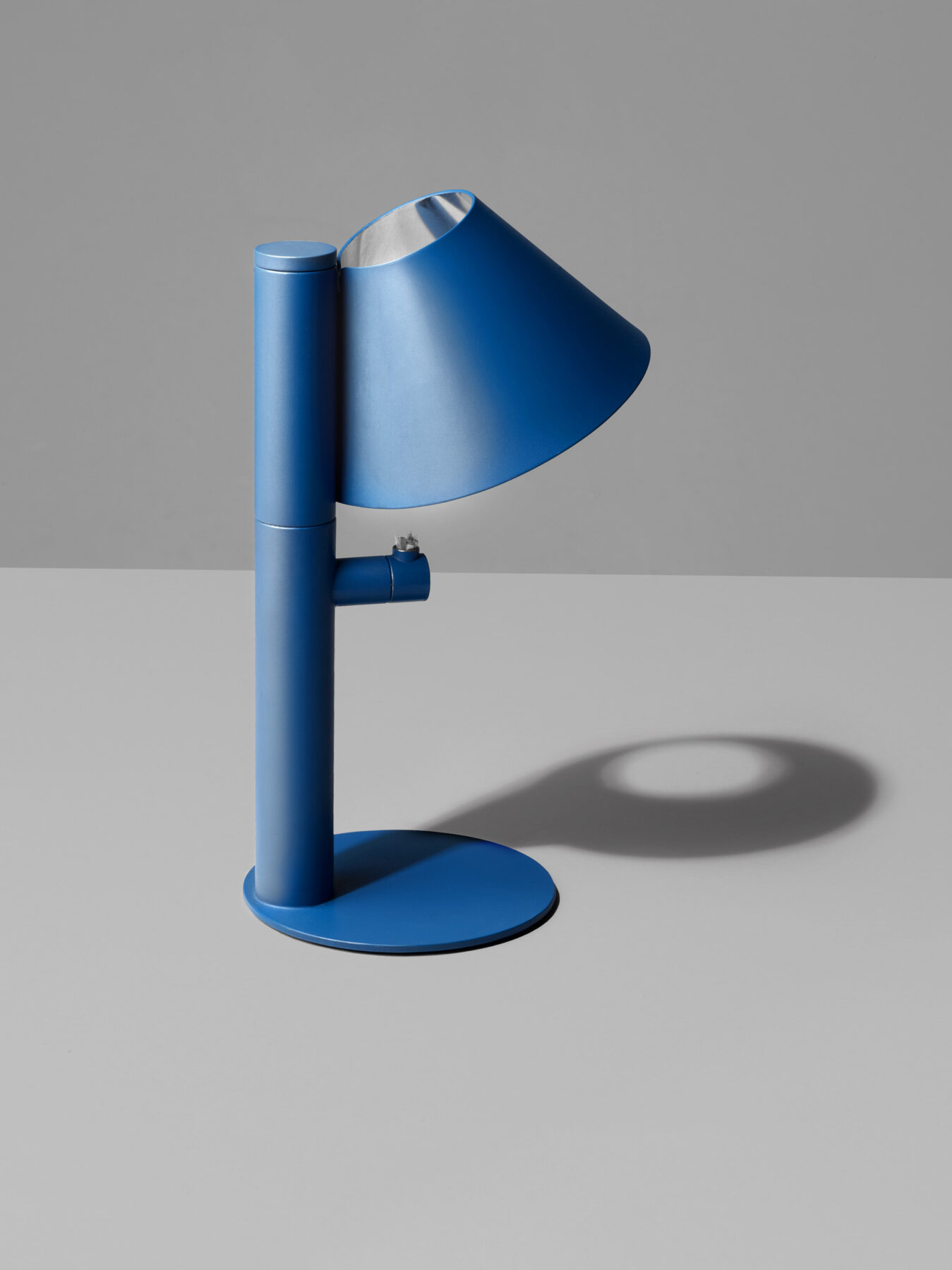

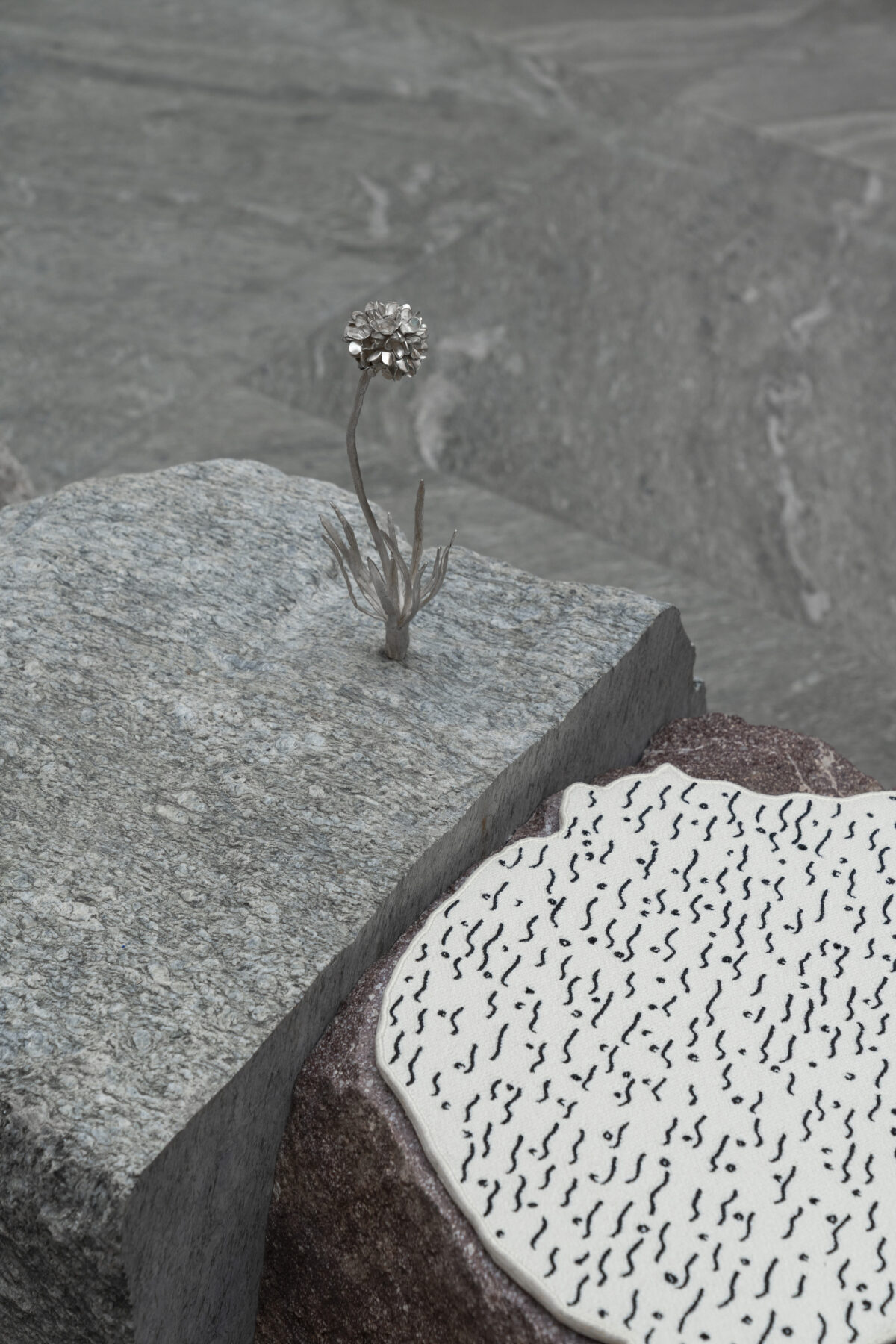

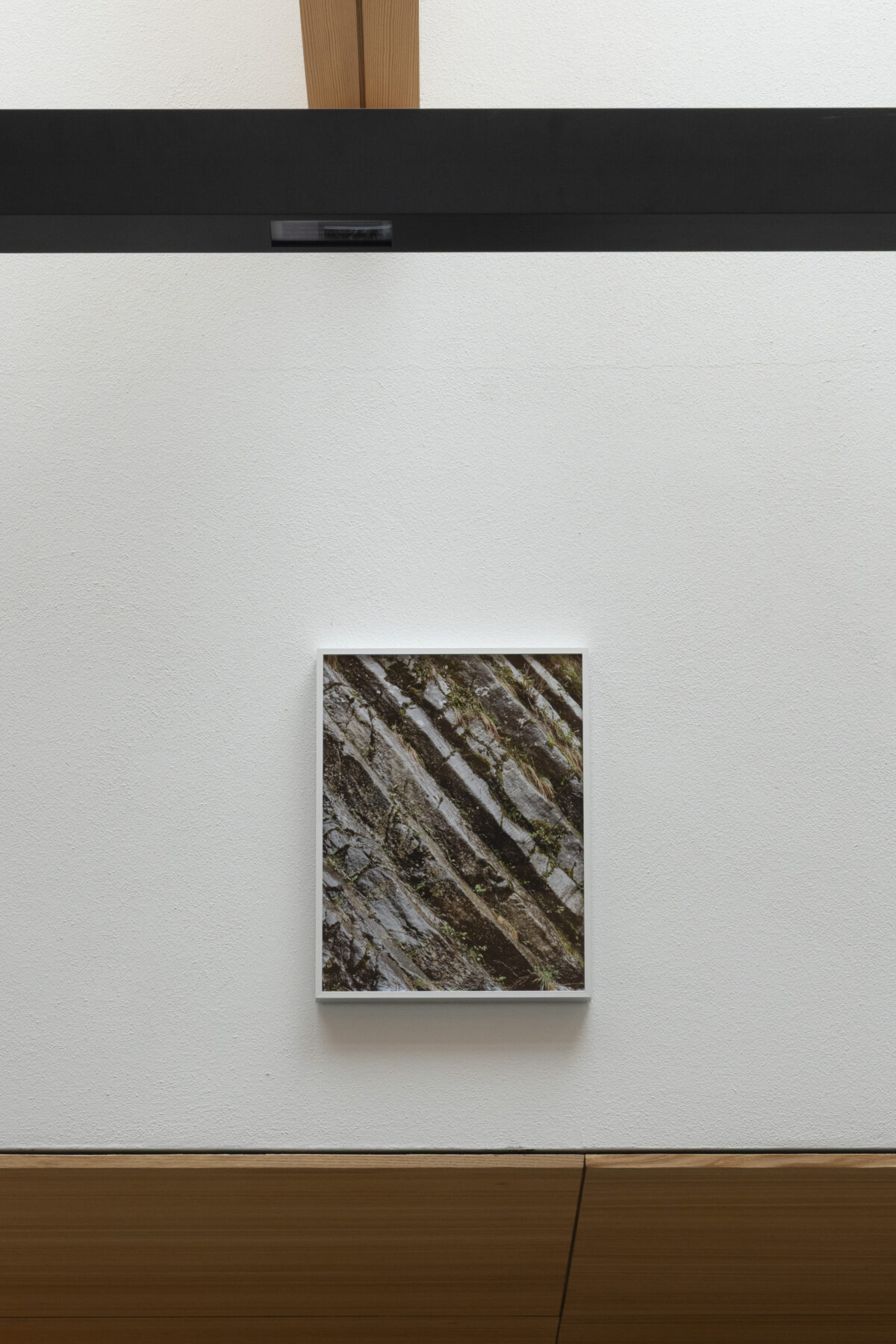

At its heart, six local glacial erratics form a bench, inviting visitors to pause before their appointments. Silver-cast flowers, embroidered cushions, and a photo series on the walls extend the narrative, evoking fairy tales of witches transformed into blooms, geological investigations in the Schlern region, and legends of giants flinging rocks across the meadows of Seiser Alm.

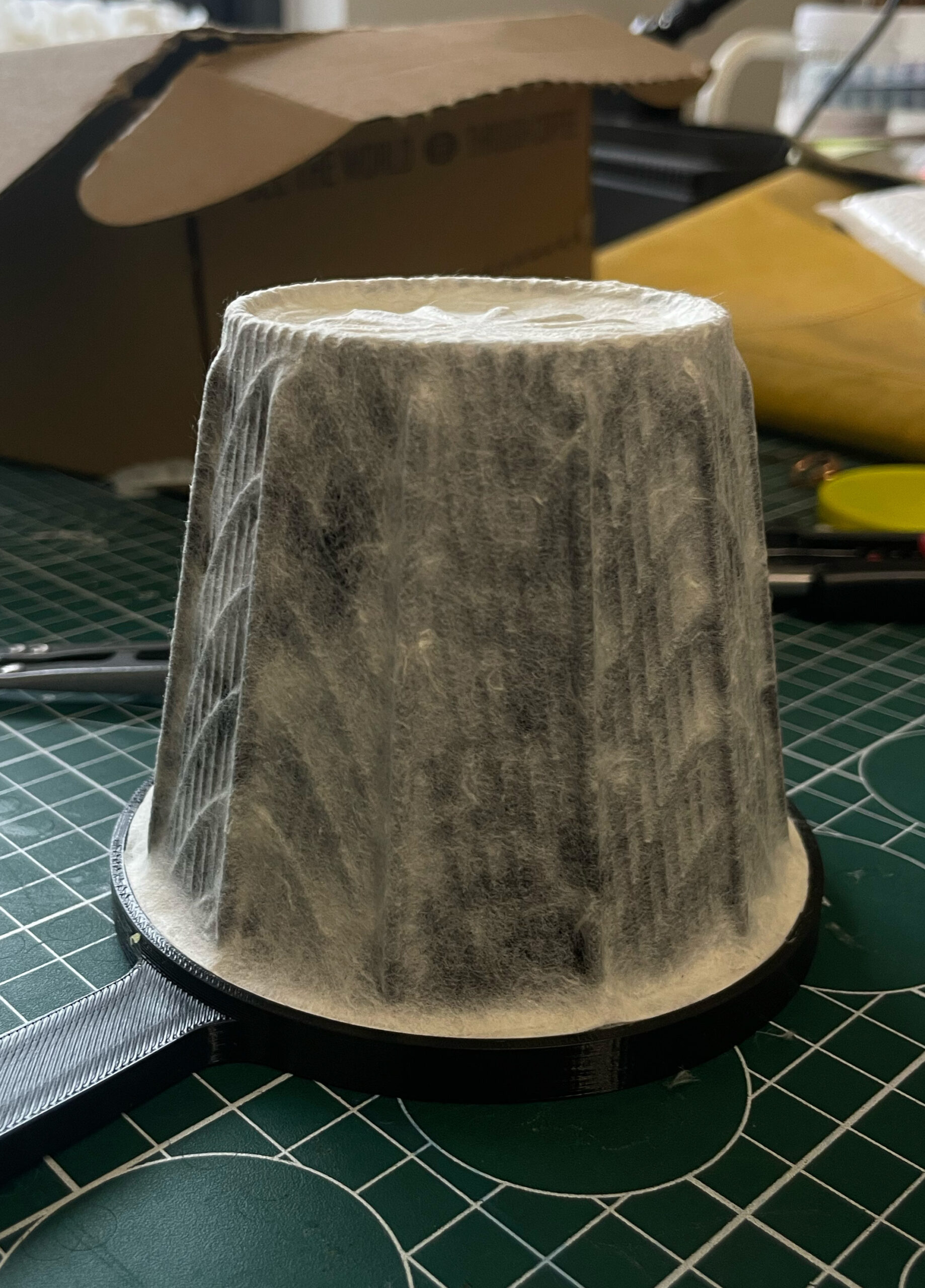

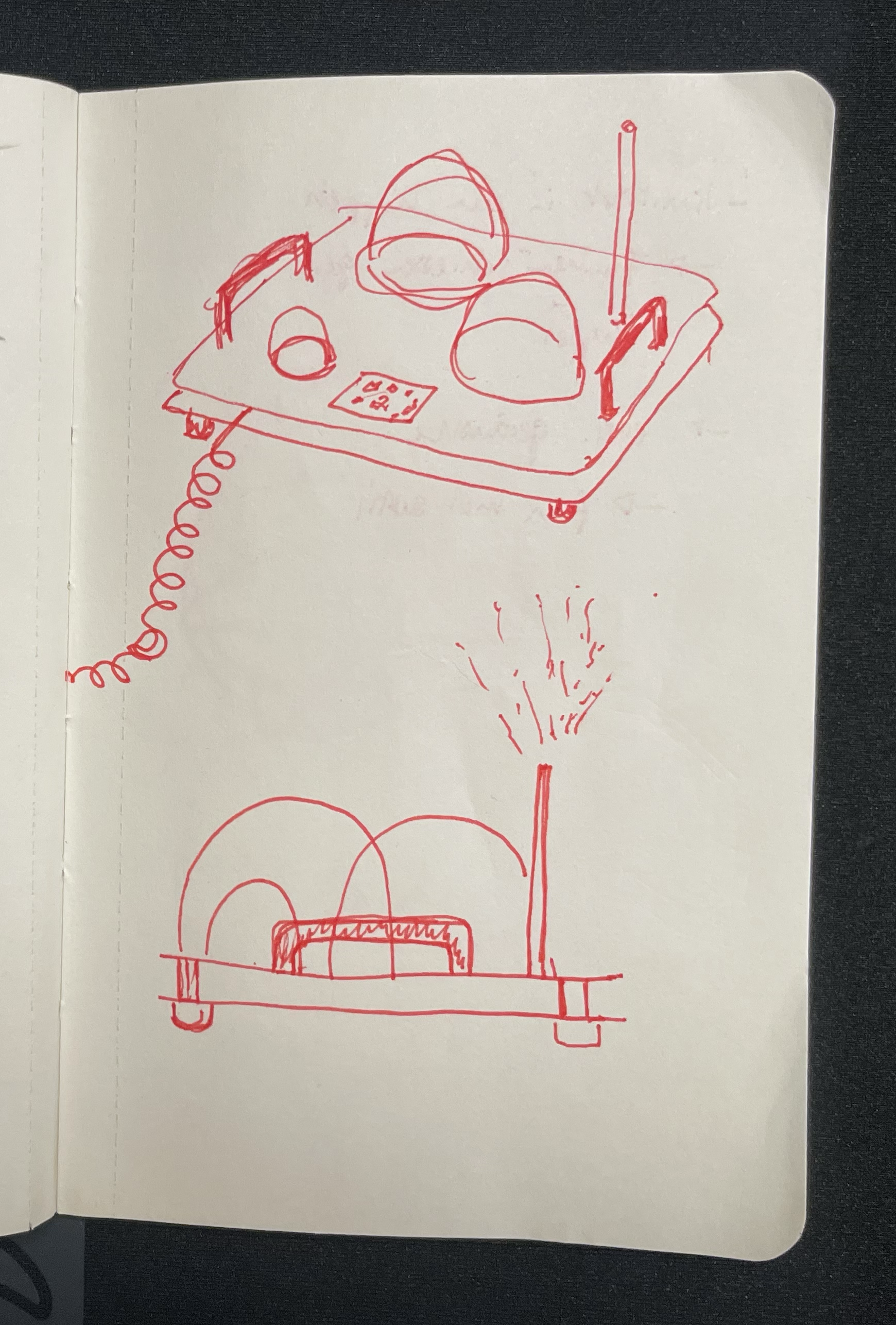

3D scan of "Kastelruther Hexenbänke"